QUALITY ASSURANCE & QUALITY CONTROL

IN THE PURSUIT OF EXCELLENCE, ORGANIZATIONS OFTEN OVERLOOK A CRITICAL DISTINCTION IN QUALITY MANAGEMENT.

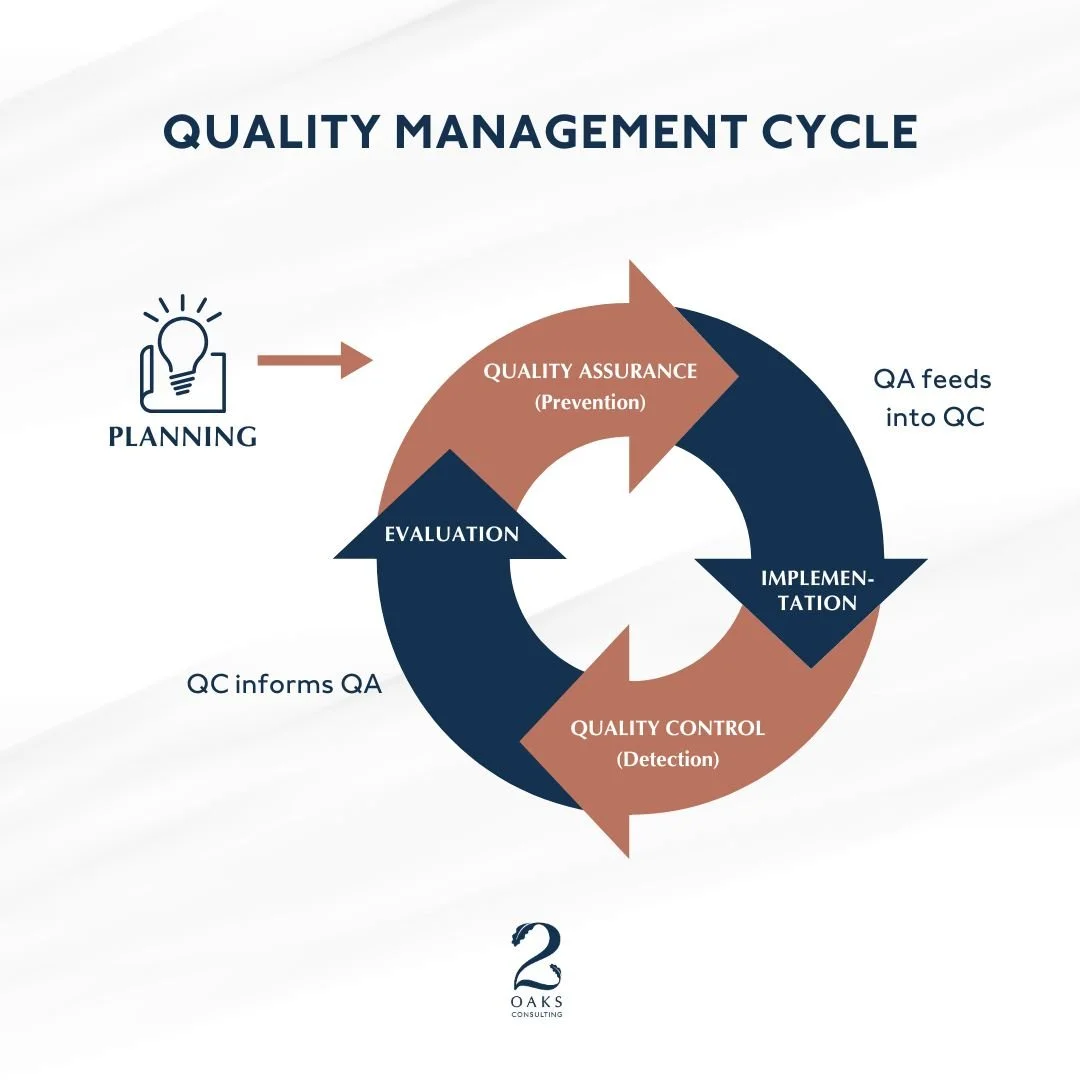

The difference between Quality Assurance (QA) and Quality Control (QC) may seem subtle, but confusing these two approaches can significantly impact a business's bottom line through costly rework, project delays, and damaged customer relationships. Like prevention and cure in medicine, these complementary but distinct strategies serve different purposes: one prevents problems before they arise, while the other addresses issues after they appear.

UNDERSTANDING THE FUNDAMENTAL DIFFERENCE

QUALITY ASSURANCE:

Quality Assurance is your prevention strategy. It's a proactive approach focused on establishing robust frameworks and standards before work begins. QA asks, "How can we prevent problems from occurring?" By implementing the right processes upfront, QA ensures consistent quality outcomes across your organization.

QUALITY CONTROL:

Quality Control, conversely, is your cure. This reactive approach involves inspecting and testing final products or services to verify they meet requirements. QC asks, "Does this output meet our quality standards?" It identifies and corrects defects in finished work.

WHEN TO APPLY EACH APPROACH

QUALITY ASSURANCE: SETTING THE FOUNDATION

QA activities should be implemented during the early stages of any project or process.

Planning Phase: Establish quality standards and methodologies

Design Phase: Create frameworks ensuring quality

Development Phase: Implement preventive measures

Process Review: Conduct regular audits and improvements

QUALITY CONTROL: VERIFYING RESULTS

QC becomes crucial during and after the production or development process:

Testing Phase: Evaluate deliverables against requirements

Pre-Release: Verify final quality

Post-Production: Monitor and test outputs

Problem Resolution: Address identified issues and defects

THE IMPACT OF PROPER IMPLEMENTATION

BENEFITS OF AN EFFECTIVE QUALITY CYCLE:

Organizations that effectively balance both QA and QC can expect:

Reduced Costs: Preventing defects is typically less expensive than fixing them

Improved Efficiency: Clear processes and standards streamline operations

Consistent Quality: Reliable outputs that meet or exceed expectations

Enhanced Reputation: Better customer satisfaction and market position

Moreover, well-designed quality processes help organizations overcome common human limitations. QA frameworks provide guardrails that reduce the impact of individual bias, inexperience, and assumptions. Systematic QC processes catch errors that might slip through due to fatigue, stress, or momentary lapses in concentration.

In other words, quality processes help maintain consistency regardless of the different people involved, ensuring high standards even during challenging times. Together, they create a safety net that protects against the natural variability in human performance and judgment.

REAL-WORLD EXAMPLES

E-COMMERCE PLATFORM LAUNCH

A major retailer launching a new website demonstrates the critical interplay between QA and QC:

QA (Prevention): The team designs the system with non-functional requirements in mind, establishes clear solution blueprints, and conducts peer engineering reviews during development to ensure the site can handle Black Friday traffic.

QC (Detection): The team tests the delivered code before it goes to production and identifies any issues back to the development team.

Lesson: Without proper QA, the site might have crashed under peak traffic, leading to lost sales and negative reviews.

AI-BASED FRAUD DETECTION SYSTEM

A financial services company implementing new fraud detection shows how QA and QC work together:

QA (Prevention): The team defines accurate fraud detection rules and trains the AI with high-quality data before deployment.

QC (Detection): Monitoring reveals an unusually high number of false positives. The team adjusts detection thresholds based on real-world performance.

Lesson: Relying solely on post-deployment adjustments would have frustrated customers with unnecessarily blocked transactions, leading to reputational damage and lost business.

PITFALLS AND BEST PRACTICES

COMMON PITFALLS TO AVOID

The most dangerous misconception is that testing alone constitutes a complete quality strategy. Testing is a QC activity - essential but insufficient without proper QA frameworks. Organizations focusing solely on QC often face:

Escalating costs from constant rework

Extended project timelines

Higher risk of major quality issues Inconsistent project outcomes

BEST PRACTICES FOR IMPLEMENTATION

To maximize the effectiveness of your quality management strategy:

Establish Clear Standards: Define specific, measurable quality criteria aligned with organizational goals and customer expectations.

Document Everything: Create comprehensive, accessible documentation for all quality-related processes.

Invest in Training: Ensure team members understand both QA and QC principles and their roles in maintaining quality.

Review Regularly: Continuously evaluate and improve quality management processes based on feedback and results.

Choose the Right Tools: Implement appropriate technologies for both QA and QC activities that support your quality objectives.

CONCLUSION

EXCELLENCE IN QUALITY MANAGEMENT REQUIRES BOTH PREVENTION AND DETECTION

Quality Assurance provides the foundation by preventing issues before they occur, while Quality Control verifies that outputs meet required standards. Organizations that master this balance achieve:

Sustainable growth through consistent quality

Improved operational efficiency

Enhanced customer satisfaction

Reduced costs through prevention

Quality is not about fixing problems. It requires creating an environment where excellence is the natural outcome of well-designed processes and thorough verification procedures.

2Oaks Consulting specializes in helping businesses implement effective quality management strategies. Our experienced team can assess your current processes and help you build the right balance of QA and QC practices for your organization. Contact us to discuss how we can help strengthen your quality management approach.

DOWNLOAD THE PDF DOCUMENT BELOW (CLICK ON THE IMAGE)

ABOUT 2OAKS

2Oaks emerged from deep within the banking sector, where our founders personally navigated the challenges of core system modernization. This hands-on experience shaped our unique approach to technology consulting -one that combines technical expertise with practical wisdom. We're not your typical consultancy. As a vendor neutral partner, we work exclusively for our clients' interests across banking, financial services, retail, and public sectors.

What sets us apart is our commitment to co-creation and knowledge transfer. We work alongside your team, ensuring that our solutions aren't just implemented but truly integrated into your organization. Our lean, efficient approach eschews unnecessary complexity in favour of practical, results-driven outcomes. Whether you're facing a system transformation, technology upgrade, or strategic shift, reach out to 2Oaks to discover how our principled, authentic approach can drive your success.